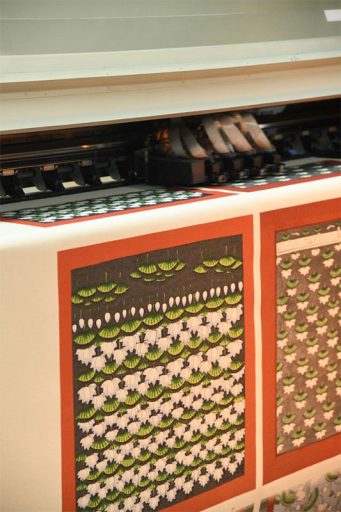

Our state-of-the-art facilities have significantly expanded over the past 5 decades.

Poornima started with a 500 sq.f t. space in 1974, at a small storefront in Tripolia Bazaar, a private entrance to the Jaipur City Palace.

Within the next decade or so, our space increased to 4000 sq.ft.

Today, Poornima’s total facilities are over 1.5 lakh sq. f t. since 2014 at theSitapura location.